Customer Specific Requirements

Each application has different requirements. Charging profiles, and load profiles differ but also the operational conditions like temperature, mechanical stress as well as available space and weight restrictions. Does the battery operate in space (under vacuum conditions), in wet environments, etc? Therefore we suggest customers start by filling in the Requirements Sheet.

For some specific applications, a specific cell is needed, especially when space is a premium in small appliances. See https://kurt.energy/custom-made-hybrid-supercapacitor-cells-and-batteries/ for some examples. Often such applications need an energy-type of cell and only 1 o 2 cells are used in the applications.

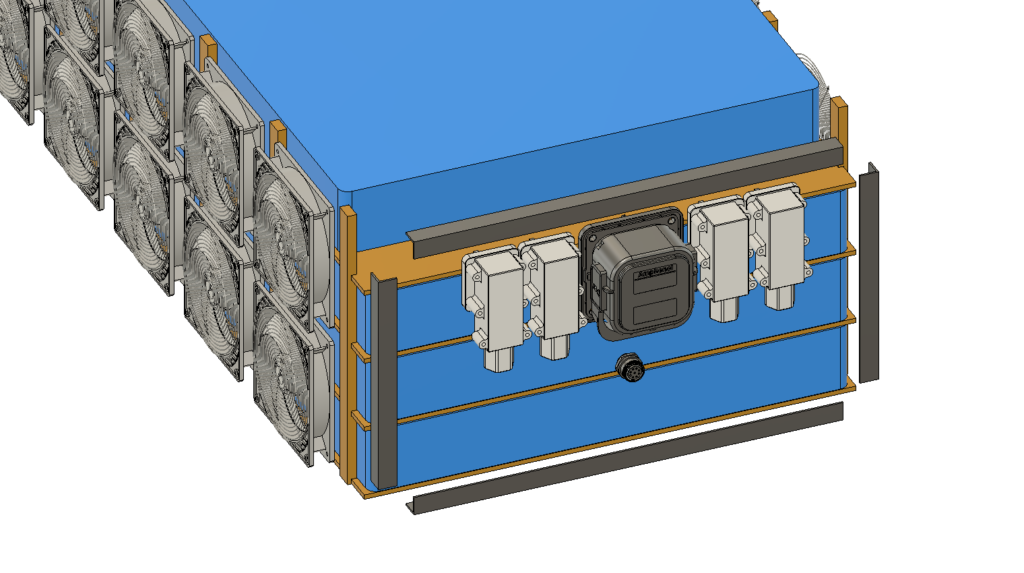

In general, a good design requires a good analysis of the system and its application. Based on this input we select the best cell type, configure one or more suitable battery configurations, propose adequate packaging (aluminum, steel, stainless less, ….), and add the required safety devices like protection circuits, BMS, fuse-switches, touch-safe connectors, cables, voltage indicators, etc.

Below are some examples of previous projects.

Most of our hybrid supercapacitor batteries are customer-specific.

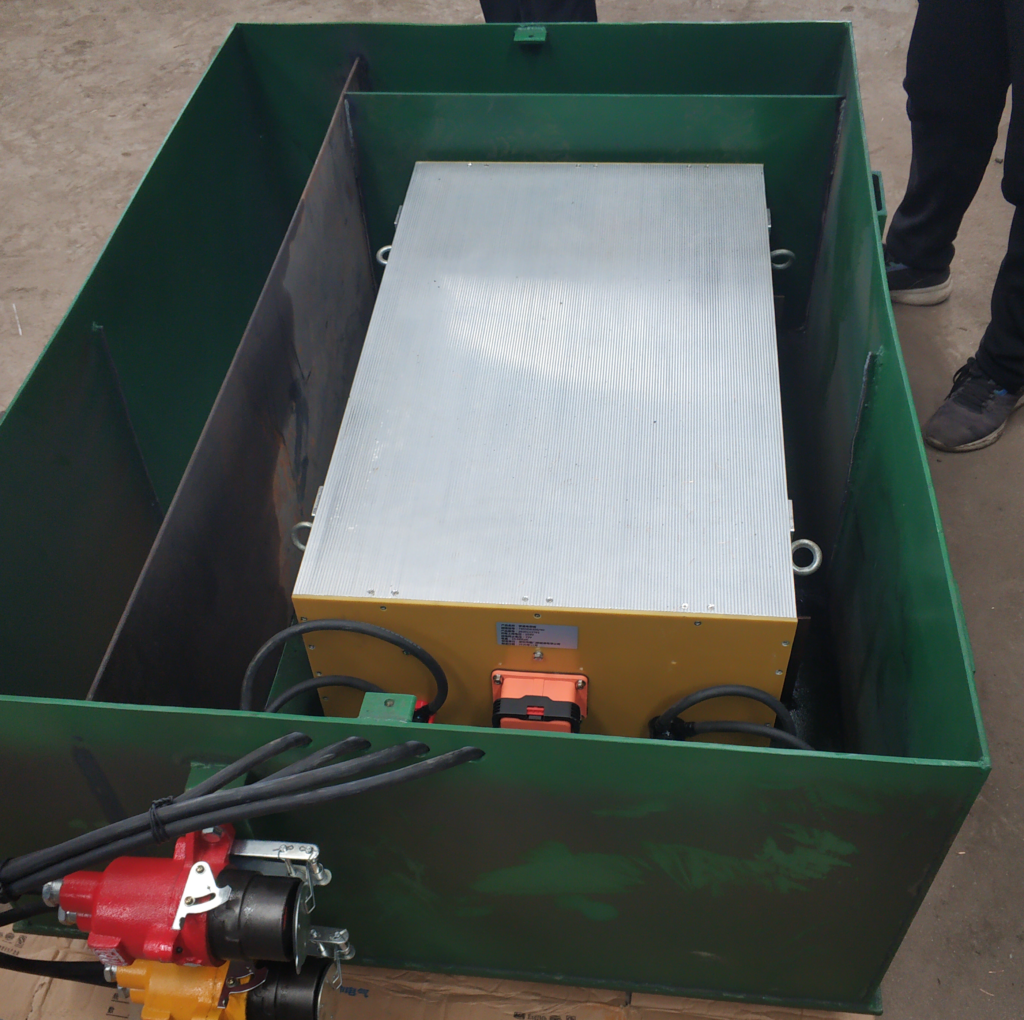

Hybrid supercapacitor batteries have many benefits for industrial vehicles like forklifts and AGVs. They charge very fast, operate in cold and hot environments and have a long lifetime with close to zero maintenance. Hence the ROI is much higher as the vehicles can operate 24/24 and might even outlive the vehicle.

Heavy batteries

Hybrid Supercapacitors often find use in heavy high-performance batteries in applications such as

- Hybrid drives, such as a 300 kW system using 250 kW fuel cells with a 30 kWh hybrid supercapacitor battery.

- Hybrid generators, such a 200 kW fuel cell with a 25 kWh hyrid supercapacitor battery.

- Battery-electric trains, using 1 to more MWh hybrid supercapacitor batteries.

- Battery-electric or hybrid ships and ferries, using 1 to 10 MWh hybrid supercapacitor batteries

- High energy storage and grid stabilisation, from a few kWh to several 10’s of MWh.

These large systems often use the 18500 cells when the C-rate is < 3C or 18650 cells when the C-rate can reach > 10C. This allows fast charging and discharging. Hence a 20 kWh pack be drained at up to 250 kW till depleted. Benefits are no BMS, no active cooling (except some air ventilation), safety (no fire risk), and a lifetime of upto 30 years (depending on the load profile) with close to zero maintenance. Large batteries are composed by putting several packs in parallel, e.g. 60 packs of 30 kWh provide 1.8 MWh. Typical voltage are between 450 and 800 VDC.